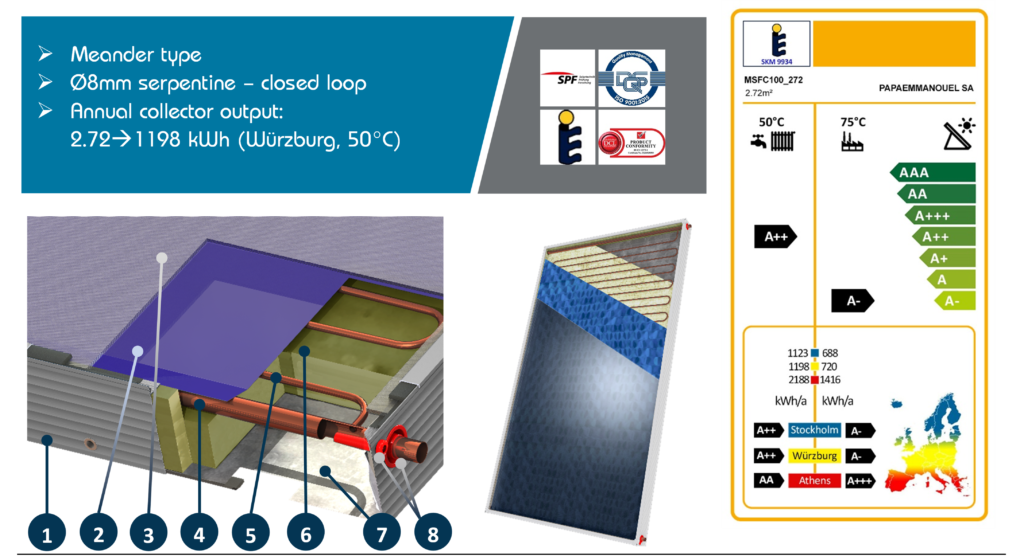

solar flame MSFC100

Solar Flame MSFC100

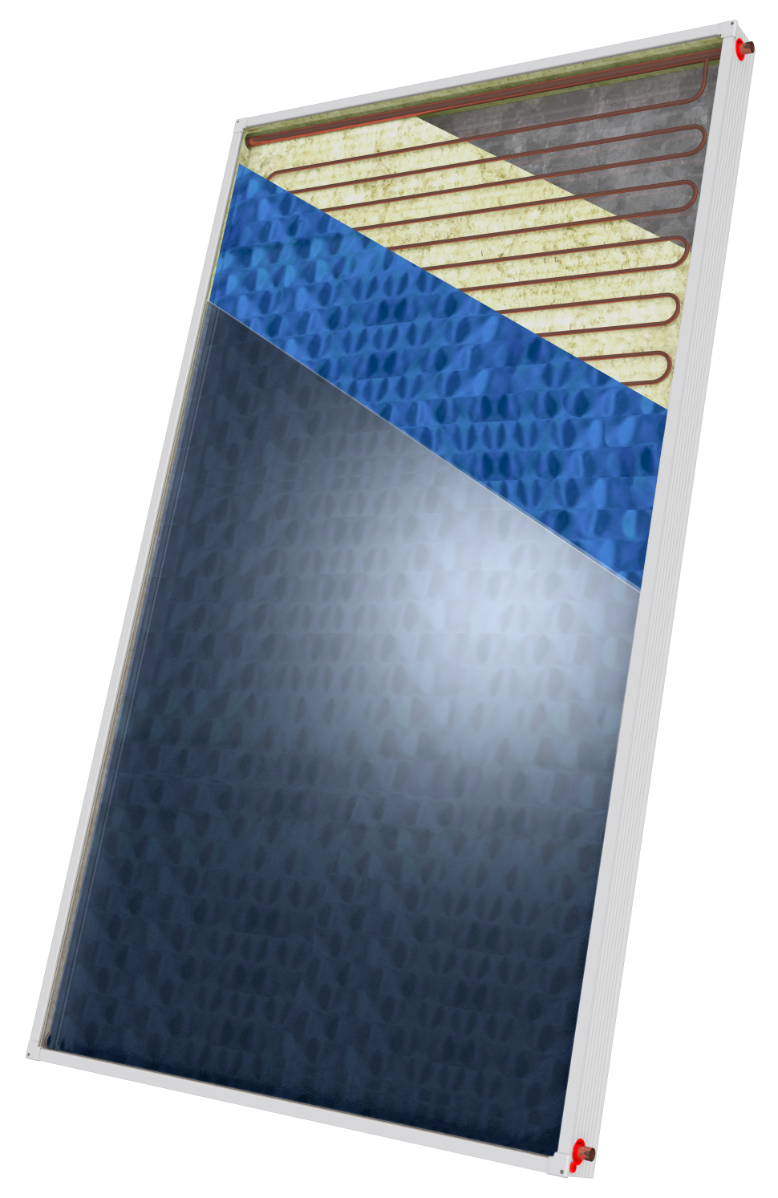

| Model MSFC100 is a superior flat plate collector encasing meander absorber with very high efficiency level. It is best suited for closed loop / forced circulation systems, small or large scale, great choice for mild and cold climates. The efficiency factor of MSFC100 is η0=0.83 (based on aperture area), making MSFC100 a powerful collector. This collector has been tested in SPF laboratory and is certified with SOLAR KEYMARK. |

|

Description: 1. Frame of the collector: Aluminium profile powder coated for maximum protection in seaside areas. 2. Absorbing surface: Aluminium surface with blue titanium high selective treatment with high absorption and low emission (α=95%, ε=4%), laser welded on the copper water frame. 3. Transparent cover: Security-Tempered prismatic solar glass for maximum protection against extreme weather conditions and temperature changes. 4. Header of water frame: Copper tubes Ø22, which is welded to the serpentine tube with hard silver solder. Each water frame is tested at the pressure of 15 bars. Headers are punched with upper expansion for perfect fitting with vertical tubes and minimum pressure drop in the collector. 5. Meander: Single serpentine, Copper tube in diameter Ø8mm. 6. Thermal insulation: 50mm thick layer of prepressed mineral wool special for solar panels for minimum thermal loss. Thermal conductivity: 0=0.035 W/m°K (EN 13162) and heat capacity 0.84 kJ/kgK. 7. Back cover: Aluzinc 0,4mm thick. Aluzinc stands for aluminium and zinc, fused in almost equal proportions, as a coating for the steel sheet that is coated with a silvery spangle composed of Aluminium (55%), Zinc (43,4%) and a touch of Silicon (1,6%). Great mechanical strength and 7 times more resistant to corrosion than common galvanized steel. 8. Sealing materials: For perfect waterproof finish and proper ventilation of collectors casing, all materials used (EPDM, polyurethane sealant, silicon air vents and silicon header flanges) resist to extreme weather conditions and temperature changes. The collector can be installed on a flat roof, tiled roof and in-roof. |

Standard solution - with normal shaped headers | ||

| ||

A. Row outlet to circulator | B. Parallel connection | |

|  | |

C. Row inlet from circulator | ||

| ||

Optional solution - Fast connections kit with special shaped headers | ||

| ||

A. Row outlet to circulator | B. Parallel connection | |

|  | |

C. Row inlet from circulator | ||

| ||

Steel supports | ||

| ||

1.a One collector on flat roof | 1.b One collector on sloped roof | |

|  | |

2.a Two collectors on flat roof | 2.b Two collectors on sloped roof | |

|  | |

3.a Three collectors on flat roof | 3.b Three collectors on sloped roof | |

|  | |

Aluminum frame supports | ||

| ||

1.a One collector on flat roof | 1.b One collector on sloped roof | |

|  | |

2.a Two collectors on flat roof | 2.b Two collectors on sloped roof | |

|  | |

Model | 1.50 V | 1.82 V | 2.00 V | 2.37 V | 2.72 V | |||||

Gross area [m²] | 1.50 | 1.82 | 2.00 | 2.37 | 2.72 | |||||

Total Dimensions [mm] | L:1480 W:1010 H:100 | L:1480 W:1230 H:100 | L:1980 W:1010 H:100 | L:1930 W:1230 H:100 | L:2160 W:1260 H:100 | |||||

Weight empty [kg] | 29.50 | 31.00 | 36.00 | 46.00 | 53.00 | |||||

Max. operating Pressure [bar] | 10 | |||||||||

Thermal Liquid Capacity [lt] | 1.40 | 1.70 | 1.64 | 2.00 | 2.20 | |||||

Collector front Cover-Thickness | LOW IRON TEMPERED GLASS 3.2mm | |||||||||

Insulation | 50mm MINERAL WOOL, λ=0.035 [W/(mK)] | |||||||||

Casing Material | ALUMINUM POWDER COATED | |||||||||

Sealing Materials | POLYURETHANE - SILICON - EPDM | |||||||||

Absorber Area [m²] | 1.38 | 1.72 | 1.86 | 2.23 | 2.57 | |||||

Water-frame type/material/diameter | Meander type ø8, copper, ø22 headers | |||||||||

Nr. Of passes | 18 | 18 | 24 | 24 | 26 | |||||

Absorber Material-Treatment | ALUMINUM / PVD COATING / HIGH SELECTIVE – A=0.95±0.02 / e=0.05±0.02 | |||||||||

Absorber construction Type | LASER | |||||||||

Heat transfer Medium | GLYCOL + WATER MIXTURE | |||||||||

Tests and Certifications | SOLAR KEYMARK | |||||||||

EFFICIENCY VALUES BASED ON EN12975 STANDARD (SKM9934) | ||||||||||

Efficiency η0 | 0.83 | |||||||||

Thermal loss a1 [w/(m²K) ] | 4.15 | |||||||||

Thermal loss a2 (w/(m²K² ) | 0.008 | |||||||||

IAM (Κθ at 50°) | 0.85 | |||||||||

Stagnation temp. [°C] | 205 | |||||||||

ηcol | - | |||||||||